|

|

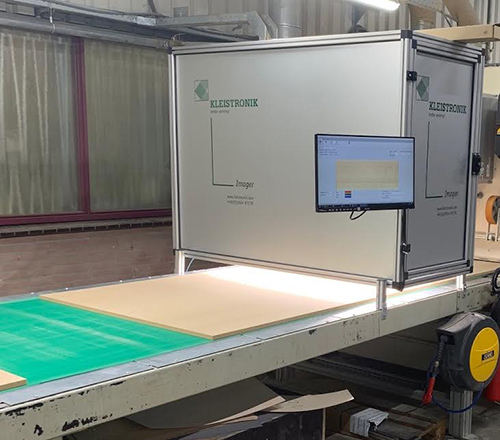

IMAGER With its special camera and illumination technology, the imager provides distortion-free images from the beginning to the end of each veneer. Optimum color capture and depth of field are guaranteed. Thus, this system enables first-class and high-resolution product images to be taken in the material flow. The benefits of the technology are obvious:

|

|

Wood is a living surface. The structure, grain and color of the different types of wood are as different and unique as a fingerprint. It is equally demanding to take detailed pictures of this natural product. The SurfaceAnalyzer is the consistent further development of the successful KLEISTRONIK imager. The imager provides a system together with the most modern software for the recording of veneers in the throughput. The system delivers high-quality images that are unique in terms of their detail accuracy and representation of the true color. Images of the veneers can be taken from the top or bottom as well as from both sides simultaneously. This ensures a very versatile field of application. The images taken are further examined in the components of the SurfaceAnalyzer. A wide variety of application scenarios are possible, such as the examination of wood species for defects (e.g. sapwood, knotholes, discoloration, bullet holes, etc. For each type of wood and quality, it is possible to determine which defects in the surface should be examined. In addition, the defects can be specified so that knotholes in spruce wood, for example, are not considered defects. |